The 2006 Winter Olympics in Turin, Italy, was getting underway when Liz McCartney, a teacher, and Zack Rosenburg, a lawyer, walked into the “hippie tent,” a meal center in Chalmette, LA, run by the unconventionally dressed members of the Rainbow Family.

The couple from Washington D.C. had driven down to help victims of Hurricane Katrina rebuild. They didn’t know how to operate most of the power tools they had borrowed from D.C. friends. And they certainly had no idea what “batch” and “flow” production were.

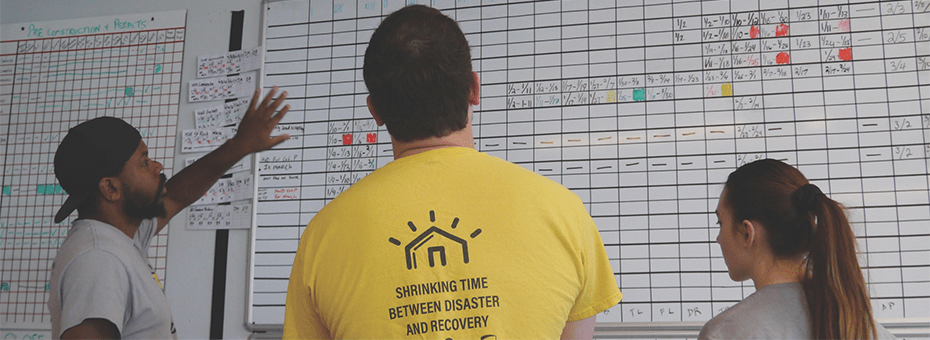

But by 2012 the disaster recovery nonprofit they founded, SBP, had cut rebuilding time by nearly 50% using lean management concepts they had learned from Toyota. Today SBP has rebuilt homes for more than 1,500 families with the help of 180,000 volunteers in 11 communities across the United States and Puerto Rico.

Their remarkable story and the remarkable new recovery model they developed based on lean concepts – which dramatically improves the lead time between disaster and recovery – are described in their new book, Getting Home, published by the nonprofit Lean Enterprise Institute.

Lean Enterprise Institute Communications Director Chet Marchwinski recently talked with Zack about disasters and recovery. Here’s an excerpt, edited for length:

Read the entire article at https://www.lean.org/LeanPost/Posting.cfm?LeanPostId=1042