by Zack Rosenburg When we (Liz McCartney and I) first realized that sustaining continuous improvement in our work required us to become an organization of problem solvers, we also discovered that we were not thrilled with the phrase continuous improvement, which felt a bit like a hamster on a wheel. And so, with the input of […]

The 2006 Winter Olympics in Turin, Italy, was getting underway when Liz McCartney, a teacher, and Zack Rosenburg, a lawyer, walked into the “hippie tent,” a meal center in Chalmette, LA, run by the unconventionally dressed members of the Rainbow Family. The couple from Washington D.C. had driven down to help victims of Hurricane Katrina […]

by Brion Hurley I wrote a book review about the work that Toyota’s TSSC group provided to a nonprofit home rebuilding organization. Their success stories were chronicled in the new book titled, “Getting Home” from the founders of St. Bernard Project Liz McCartney and Zack Rosenburg. Some of the improvements highlighted in the book include: […]

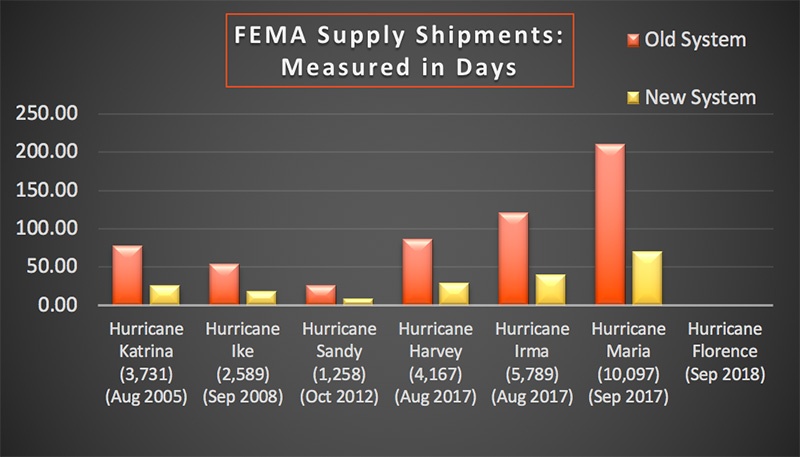

The Federal Emergency Management Agency (FEMA) has been under considerable criticism and has had dissatisfied customers for many years. Charles White (GoLeanSixSigma Green Belt) started a project to assess FEMA’s processes and to show they were in need of significant improvement. Root Cause Analysis Two bottlenecks were located at the distribution center and relief sites […]

by Brion Hurley In the wake of Hurricane Katrina, Mark Novak quickly joined a disaster relief trip to help rebuild communities in Mississippi. He soon found out there were many frustrating aspects of the process that needed to be addressed; supplies were scarce or late to arrive, communication of problems were accomplished too late in the […]

by Brion Hurley Andrew Parris has over a decade of experience working at non-profit NGO’s (Non-Governmental Organizations). He works with organizations that deal with emergency response and recovery work for countries afflicted by war and natural disasters. In his book chapter, he details how he used his Lean Six Sigma skills to enable colleagues to work […]

Toyota North America’s nonprofit group called Toyota Production System Support Center (TSSC) felt compelled to help Houston in the same way it helped New Orleans after Hurricane Katrina. TSSC has helped nonprofits become more efficient by applying Toyota principles called TPS, Toyota Production System. SBP (St. Bernard Project), a nonprofit that received help from Toyota […]

“Industrial Engineer” Managing Editor Michael Hughes interviews the three co-directors of Georgia Tech’s Center for Health and Humanitarian Logistics, which was founded in 2007. In order of appearance: Julie Swann, Pinar Keskinocak and Özlem Ergun The center works to transform the humanitarian sector by applying industrial engineering tools to groups that respond to natural and man-made disasters. The center’s […]

By 2009, four years after Hurricane Katrina hit on Aug. 29, 2005, there were 8,000-plus displaced homeowners in the New Orleans area still struggling to move back home, but who didn’t have money or insurance for repairs. Worse, they were being joined by an increasing number of homeowners who had suffered contractor fraud. “We had […]

The lean principles of the Toyota Production System are changing how New Orleans and the U.S. recovers from disasters. With help from the Toyota Production System Support Center (TSSC), they’d become unstuck, slashing lead time to just 60 days and dramatically increasing the number of quality homes rebuilt monthly. Read more at LEI: https://www.lean.org/common/display/?o=3016